Overview of Oxygen Gas in Industrial Processes

Oxygen gas plays a vital role in numerous industrial applications, from metal fabrication to chemical processing. Its ability to enhance combustion, improve efficiency, and enable high-precision cutting makes it indispensable in manufacturing and heavy industries. In metal production, oxygen is used to increase the temperature of furnaces, helping to accelerate melting and refining processes. It also plays a crucial role in chemical manufacturing, where it supports oxidation reactions necessary for producing various chemicals and materials.

Furthermore, oxygen is essential in the glass and ceramic industries, aiding in improving product quality and reducing production time. Coregas provides high-purity oxygen to support these critical processes, ensuring consistent performance, enhanced productivity, and improved safety standards across industries. By supplying reliable and high-quality oxygen gas, Coregas helps industries maintain operational efficiency and meet production demands with greater precision.

Role of Oxygen in Metal Fabrication and Welding

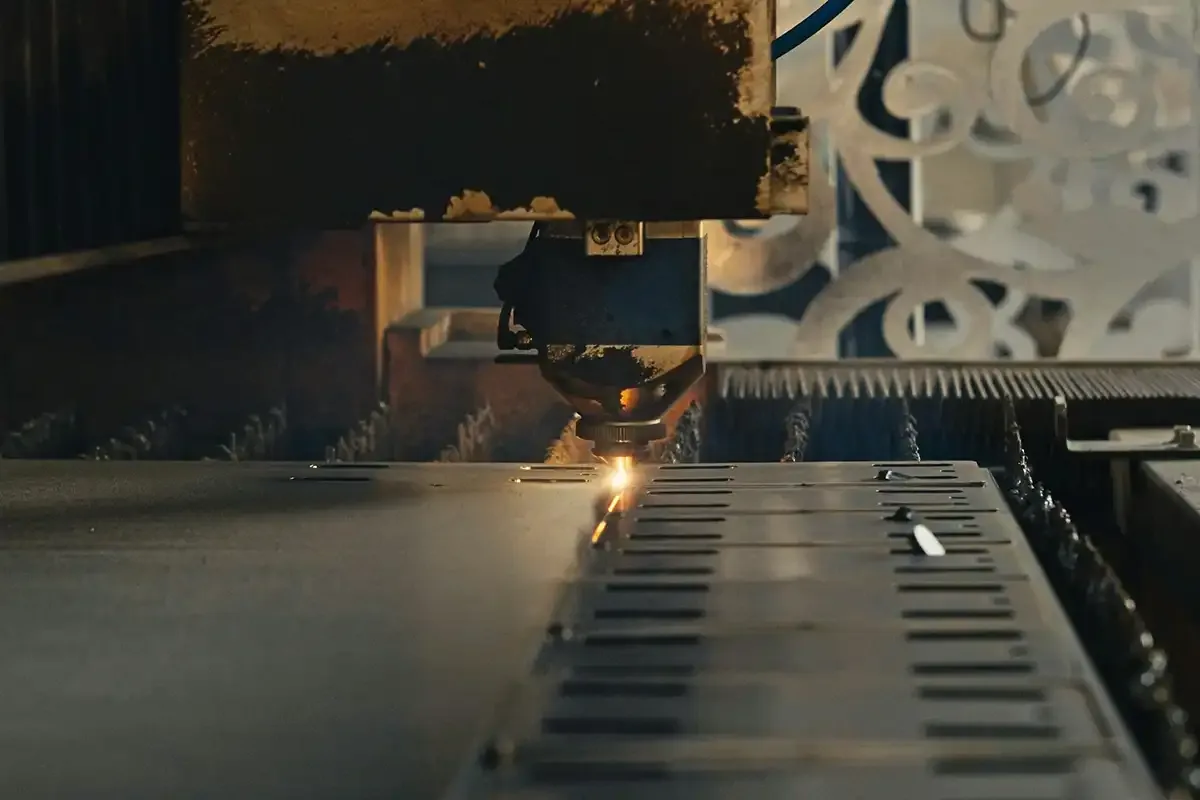

Oxygen Cutting

Oxygen is essential in oxy-fuel cutting, where it reacts with the metal at high temperatures to create a clean cut.

Products like Lascut-O enable faster cutting speeds and greater thickness at lower pressures.

Oxygen Welding

Oxygen is used with a fuel gas like acetylene for welding and brazing.

Trade N Go Gas™ Oxygen 2.5 provides a reliable solution for precise welding and soldering.

Metal Processing

Oxygen is used in steelmaking to remove impurities and enhance alloy formation.

Industrial-grade oxygen, such as Oxygen 2.5, is designed for efficient metal treatment.

Safety Considerations When Handling Oxygen

Handling oxygen requires strict safety measures due to its highly reactive nature and the increased risk of fire. Oxygen itself is not flammable, but it supports and accelerates combustion, making materials ignite more easily and burn at higher temperatures. Even a small spark can cause a dangerous fire when oxygen levels are elevated, so understanding and following proper safety protocols is essential.

Proper ventilation is crucial when working with oxygen to prevent the buildup of gas, which could lead to an increased fire hazard. Adequate airflow helps disperse excess oxygen and reduces the risk of accidental ignition. Workspaces should be equipped with ventilation systems designed to handle oxygen-rich environments, ensuring a safe working atmosphere.

It’s important to keep oxygen away from oils, greases, and other organic materials, as these substances can react violently with oxygen and ignite spontaneously. Even small amounts of contamination on equipment or clothing can trigger combustion, so all tools and surfaces should be kept clean and free from flammable residues.

Using the appropriate personal protective equipment (PPE) is essential when working with oxygen. Fire-resistant gloves, eye protection, and flame-retardant clothing can protect workers from potential burns and injuries. Training staff on the correct handling and storage procedures for oxygen further enhances safety and reduces the likelihood of accidents.

How Coregas Ensures High-Purity Oxygen Supply

At Coregas, delivering high-purity oxygen is a top priority. Strict quality control measures are in place at every stage of production to ensure consistent purity and performance.

Every batch undergoes rigorous testing to meet the precise standards required for industrial applications, whether it's for metal fabrication, chemical processing, or other high-demand uses.

Reliable delivery is key to keeping operations running smoothly. With a strong distribution network across New Zealand, oxygen is delivered quickly and efficiently, ensuring that supply meets demand without delays. Flexible delivery options make it easy to stay stocked and avoid interruptions in production.

Safety always comes first. All handling, storage, and transportation of oxygen follow strict safety regulations to reduce risk and maintain a secure working environment. Proper training and well-maintained equipment ensure that oxygen is handled with care, minimizing potential hazards.

Want to learn more about how oxygen purity impacts industrial performance? Explore more about high-purity oxygen and its applications here.

How to Safely Handle Oxygen

- Store Properly: Keep cylinders upright and secured.

- Avoid Contamination: Keep oxygen away from flammable materials.

- Check Regulators: Ensure all valves and regulators are in working order.

- Use Compatible Equipment: Only use oxygen-rated hoses and connectors.

- Ventilate Work Area: Ensure proper airflow to prevent gas buildup.

- Emergency Response: Train staff on emergency shutoff procedures.

Coregas Oxygen Gas

Enhance your industrial performance with high-purity oxygen from Coregas. Explore our range of oxygen products:

- Lascut-O – High-speed cutting.

- Oxygen 2.5 – Reliable for cutting, welding, and brazing.

- Trade N Go Gas™ Oxygen 2.5 – Flexible, portable welding solution.

Ensure your industrial processes are efficient and safe with Coregas oxygen solutions.