In the dynamic landscape of industrial applications, the purity of oxygen is paramount for achieving optimal performance and safety. As a market leader in the field, Coregas is at the forefront of providing high-quality oxygen tailored to meet the diverse needs of various New Zealand industries. With a comprehensive understanding of market requirements, we specialise in producing oxygen across a wide range of purities, ensuring that whether you need laser grade, industrial grade, food grade, aviation grade, or laboratory grade oxygen, Coregas delivers to your specifications.

Our commitment to quality, coupled with our competitive industrial oxygen price, positions us as a trusted partner for businesses looking for a reliable supply of oxygen. At Coregas, we recognize that each industry has unique supply needs, and our professional team is ready to assist you in identifying the right oxygen solution for your specific application. Whether you have questions about our products, pricing, or how to create an account, don't hesitate to reach out. For those in need of oxygen that meets stringent quality standards, Coregas is your go-to source for excellence in the industrial production of oxygen.

Understanding Oxygen Purity

Oxygen is produced in various purity levels, each designed to meet the specific requirements of different industrial applications. The following are common purity grades:

Industrial Grade Oxygen (Oxygen 2.5):

This grade is typically used for general industrial applications such as welding and cutting. It provides sufficient purity for processes that do not require extremely high standards.

Laboratory Grade Oxygen (Oxygen 4.0 and Oxygen 5.0):

Designed for scientific research and critical experiments, these grades require higher purity levels. Oxygen 4.0 contains 99.996% purity, ensuring minimal impurities that could interfere with sensitive laboratory analyses. Oxygen 5.0, with a purity of 99.999%, is often used in high-precision environments where accuracy is crucial.

Food Grade Oxygen:

This grade is essential for food packaging and storage as it ensures that the oxygen used does not adversely affect food quality and safety. Compliance with food safety standards is critical in this application.

Aviation Grade Oxygen:

Required for use in aviation systems, this grade meets stringent safety and purity regulations to ensure passenger well-being during flights.

These purity levels ensure that oxygen can effectively serve its intended applications without compromising quality or safety.

Physical and Chemical Properties of Oxygen

Understanding the physical and chemical properties of oxygen is crucial, especially for industries that rely on its use. Here are key properties:

Appearance:

Oxygen is characterised as a colourless gas. Its lack of colour means that special instrumentation is required to detect its presence and concentration.

Odour:

Oxygen is odourless, which means it has no smell. This property is vital for safety, as the absence of scent can make it challenging to detect leaks or low levels without appropriate monitoring equipment.

Flammability:

Oxygen is classified as non-flammable. However, it is important to note that while oxygen itself does not burn, it is a powerful oxidising agent that can significantly accelerate the combustion of other materials. Therefore, it must be handled with care, especially around flammable substances.

Hazard Class:

Oxygen is categorised under two hazard classes:

2.2: Non-flammable, non-toxic gas - Indicates that the gas is non-flammable and non-toxic

5.1: Oxidizing agent. - Indicates that the substance acts as an oxidising agent, meaning it can cause or enhance the combustibility of other materials.

Oxygen chemical symbol

Given these properties and classifications, it is vital for industries to implement proper storage, handling, and transport protocols to maintain safety when working with oxygen.

What is oxygen used for in industrial applications

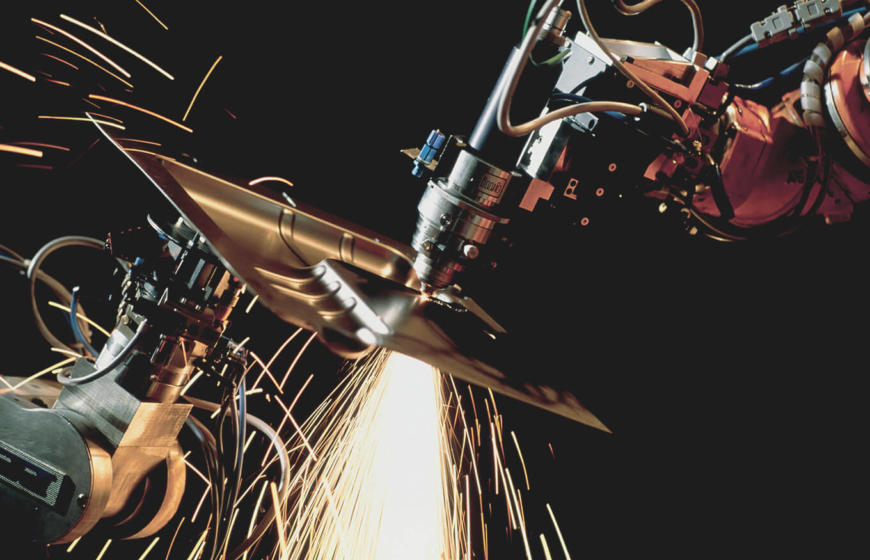

Welding and Cutting With Oxygen

High-purity oxygen is crucial in welding and cutting operations, leading to superior weld quality and reduced contamination. The properties and uses of oxygen enable it to facilitate optimal combustion temperatures, which are necessary for these processes. Industries such as construction, automotive, and manufacturing heavily rely on this purity to ensure structural integrity and quality.

Oxygen In The Food Industry

In the food industry, food grade oxygen plays a vital role in packaging and storage. By maintaining the right oxygen levels, businesses can extend the shelf life of perishable goods, ensuring that products reach consumers in the best condition. Proper oxygen purity helps inhibit microbial growth, making it essential for food safety and quality.

Aviation Industry

Aviation-grade oxygen is a critical component for aircraft systems and passenger safety. Proper oxygen levels are essential for crew and passenger health, especially during high-altitude flights. Adherence to regulatory standards and safety protocols ensures that oxygen cylinders used in aviation meet strict quality requirements, underpinning air travel safety.

Oxygen In Laboratories

Laboratories require high-purity oxygen for conducting experiments and research. Accurate measurements depend on the purity level of the oxygen used; any contaminants can lead to skewed results. Ensuring high-purity oxygen is vital for achieving reliable data, which is crucial for scientific advancement.

Consequences of Low Oxygen Purity

Quality Issues

Using low-purity oxygen can lead to severe quality problems in end products. Impurities may react with other materials, causing defects that compromise the integrity of high-grade products.

Safety Hazards

Safety hazards can arise in the workplace when low-purity oxygen is used, leading to accidents or equipment malfunction. For example, improper oxygen concentrations can contribute to unhealthy working conditions or even fires in sensitive industrial environments.

Economic Impact

The economic implications of using low-purity oxygen can be significant. Businesses may face increased costs due to defective products or processes requiring rework, ultimately affecting the bottom line. Ensuring high-purity oxygen is not just a quality standard; it is a strategic investment.

Ensuring Oxygen Purity

Quality Control Measures

Reliable suppliers like Coregas employ stringent quality control measures to guarantee oxygen purity levels. Advanced testing technologies and strict manufacturing processes ensure that every batch meets the highest New Zealand industry standards.

Certification and Standards

Compliance with industry standards is crucial. Certifications from authoritative bodies assure businesses that the oxygen they are sourcing adheres to the necessary testing protocols and purity levels required by their respective industry.

Choosing the Right Oxygen Supplier

Importance of Supplier Reliability

Sourcing oxygen from reputable suppliers is essential for ensuring purity and quality. A reliable supplier can provide tailored solutions that meet unique industrial needs.

Coregas as a Lead Supplier

Coregas offers a range of industrial-grade oxygen cylinders tailored for various applications. From large scale operations to Trade N Go gas bottle for tradies, Coregas stands out as a trusted partner for businesses in need of oxygen.

The significance of oxygen purity in industrial applications cannot be overstated. Its role extends beyond mere combustion; it affects quality, safety, and overall operational efficiency. As technology advances, ensuring the supply of high-purity oxygen offers businesses a competitive advantage in various industries. Embrace these advancements by ensuring you have the right source for your oxygen needs.

If you're looking for high-purity oxygen tailored to your specific industrial requirements, contact Coregas today! Our professional team is here to discuss your needs, provide pricing information, and assist with creating an account.